모션 제어 기술 분야의 글로벌 선두 기업인 렌제(Lenze)는 최근 금속 가공 산업에 최적화된 풀 스펙트럼 지능형 솔루션을 출시했습니다. 렌제는 첨단 하드웨어와 최적화된 소프트웨어를 통합하여 효율적인 생산과 저탄소 전환을 목표로 하고 있습니다. 이 이니셔티브는 장비 지능화 및 디지털화에 대한 시장 수요를 충족할 뿐만 아니라 금속 가공 분야의 "인더스트리 4.0"을 향한 중추적인 역할을 할 것입니다.

기술 혁신: 단일 장비에서 전체 시나리오 적용까지

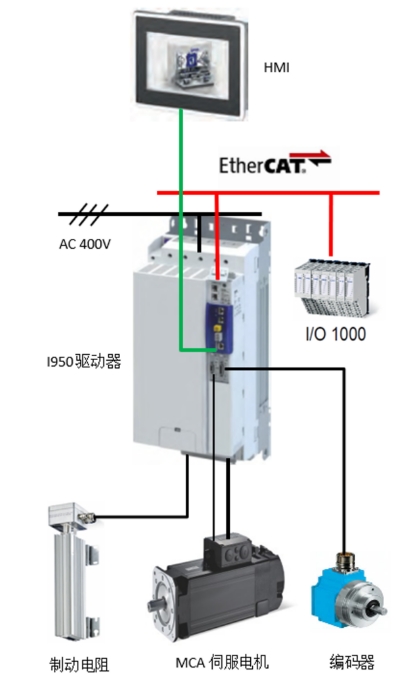

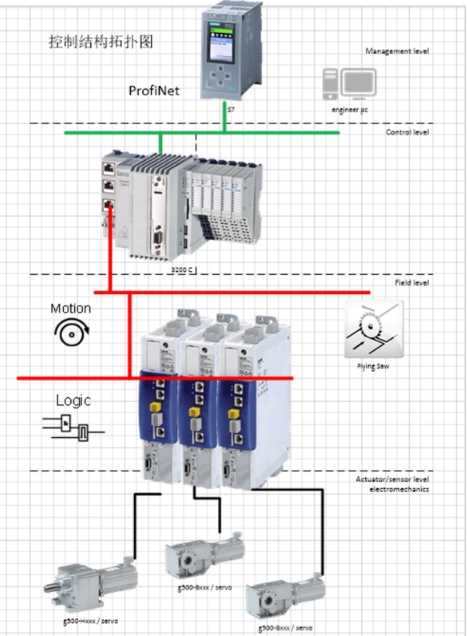

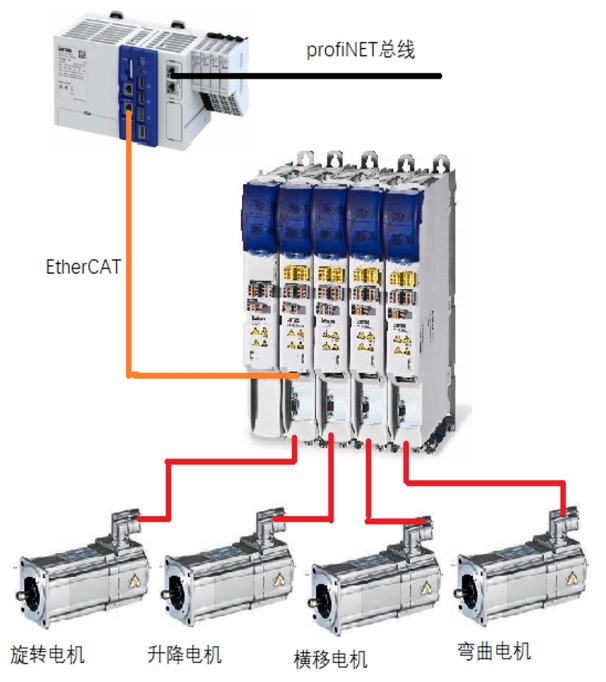

금속 가공 산업은 엄청난 변화를 겪고 있습니다. 주조, 3D 프린팅, 용접과 같은 기존 공정의 지능적인 업그레이드는 서보 드라이브와 자동화 제어의 성능 향상을 요구합니다. 렌제는 거의 80년간 축적된 기술 전문성을 바탕으로 모터, 기어박스, 드라이브, 컨트롤러를 아우르는 포괄적인 제품 포트폴리오를 구축했습니다. 렌제만의 FAST 공정 소프트웨어 제품군이 금속 가공 애플리케이션에 최초로 통합되어 개발 주기를 30% 단축하고 비용을 25% 절감했습니다.

역동적인 사례 연구:

산업 통찰력: 녹색하고 효율적인 진행

렌제(Lenze)의 중국 기술 이사는 "금속 가공의 미래는 '3대 통합'에 달려 있습니다. 생산 유연성을 위한 인텔리전스, 에너지 절감을 위한 친환경 기술, 그리고 비부가가치 시간 최소화를 위한 효율성입니다."라고 강조했습니다. 렌제 솔루션은 회생 제동을 통해 운영 에너지 소비를 18% 절감하고, 모듈식 설계를 통해 신속한 생산 라인 재구성을 지원하여 소량 생산, 다품종 생산 트렌드에 대응합니다.

미래 전략: 지역화된 혁신과 생태계 리더십

중국의 제조업 혁신 속에서, 렌즈(Lenze)는 향후 3년간 AI 비전 검사 및 디지털 트윈 기술에 중점을 두고 R&D에 5억 위안을 투자할 계획입니다. 또한, 주요 공작기계 제조업체들과 협력하여 공동 연구소를 설립하고, 업계 표준을 선도하며, 하드웨어부터 클라우드 플랫폼까지 지능형 생태계를 구축하고 있습니다.

부품 공급업체에서 풀 시나리오 솔루션 제공업체로 거듭나는 Lenze는 혁신을 통해 금속 가공 가치 사슬을 지속적으로 재편하고 있습니다. 탄소 중립과 산업 인터넷이라는 두 가지 핵심 동력 하에, "하드웨어 + 소프트웨어 + 서비스" 통합 모델은 업계 스마트 팩토리 전환의 새로운 기준을 제시할 수 있습니다.